Inside Our Kratom Drying Facility: Why the Drying Method Matters

Inside Our Kratom Drying Facility: Why the Drying Method Matters

From the Kapuas River to your door: The story of protecting kratom's natural power

We set out to bring you the purest kratom in Europe. But when we arrived in Putussibau for the first time ten years ago, we discovered something that shocked us: the traditional drying methods that worked for centuries were now destroying the very compounds that make kratom special. So we built our own facilities to dry Kratom – a controlled drying facility designed specifically to preserve kratom's alkaloid profile.

The Alkaloid Story: What Makes Kratom Work

Kratom leaves contain over 40 natural alkaloids – organic compounds that interact with your body in specific ways. The two most important are:

- Mitragynine (up to 66% of total alkaloid content)

- 7-hydroxymitragynine (a more potent compound found in smaller amounts)

These alkaloids are remarkably sensitive. Temperature, humidity, UV exposure, and contamination can all degrade or destroy them – turning premium leaves into mediocre powder.

Think of it like cooking with olive oil. Heat it too much, and you destroy the beneficial compounds. Expose it to light and air, and it goes rancid. Kratom is even more delicate.

The drying process is where quality is made or lost. You can start with the finest leaves from the best trees, but if you dry them incorrectly, you end up with an inferior product.

Indonesia's Ancient Drying Tradition

Indonesia is a country blessed with incredibly rich vegetation. Walk through any village, and you'll see something drying in the sun:

- Vanilla pods spread across bamboo mats

- Nutmeg and cloves drying on tarps

- Cocoa beans laid out in courtyards

- Cassava, corn, and rice drying after harvest

- Tobacco leaves hanging from rafters

For many of these crops, direct sunlight is perfect. The UV rays help preserve them, the heat drives out moisture, and the traditional methods work beautifully.

For centuries, this is how it's been done. It's embedded in the culture, passed down through generations.

Why Kratom is Different

But here's what we learned: kratom is not like these other crops.

Direct sunlight breaks down mitragynine. UV rays degrade the alkaloid structure. The intense tropical sun – the same sun that perfectly dries cloves and cocoa – destroys the very compounds that make kratom valuable.

We tested this. We compared kratom dried in full sun versus kratom dried in shade. The difference in alkaloid content was significant.

The traditional method that worked for everything else was failing kratom.

Where Our Kratom Grows

Our kratom comes from Putussibau, a village right along the upper Kapuas River in Kapuas Hulu regency, Kalimantan (Indonesian Borneo).

In Indonesia, there are really only two locations where kratom grows naturally: Putussibau and Sintang (another regency downstream). These are special places.

Almost every villager knows the value of kratom. They know they live somewhere unique. Walk through the village, and you'll see kratom trees in nearly every garden – some towering 10, 15, even 20 meters high.

Harvesting kratom is remarkably sustainable. You simply pick the mature leaves and let the tree keep growing. No branches are cut. No harm is done to the tree. Within weeks, new leaves mature, and you can harvest again.

So naturally, villagers dry their kratom right in their own gardens.

The Problem With Traditional Village Drying

[Insert images of traditional drying methods showing contamination issues]

Here's where modern life corrupted the ancient technique.

While Indonesians still use traditional methods, they're doing it in modern conditions – and that creates serious problems:

Roads and Vehicles Everywhere

Kratom drying on plastic sheets right next to busy roads, absorbing diesel fumes, dust, and exhaust.

Ground-Level Drying

Leaves spread directly on the ground or thin plastic tarps. Villagers sweep them with brooms that have swept everything else. People walk barefoot through the leaves. Dogs wander across them. Chickens peck at them.

No Quality Control

Different batches mixed together. No way to ensure consistent drying. No protection from contamination.

We saw this happening everywhere. Premium leaves – hand-picked from trees that took years to mature – being contaminated and degraded before they even left the village.

This was the obstacle we had to solve.

%20copy%20(1).jpg)

Our Solution: Purpose-Built Drying Facilities

We knew we couldn't just tell villagers to change methods that had worked for generations. We had to build something better.

So we did something unprecedented in this region: we built dedicated kratom drying facilities in Putussibau.

.jpg)

Our purpose-built drying facility in Putussibau

Where Our Kratom Comes From

Our kratom comes from two carefully controlled sources:

- Wild kratom growing naturally in the jungle along the Kapuas River – far from any roads, far from any contamination, growing exactly as it has for centuries

- Controlled kratom fields – dedicated farms where we work directly with local farmers, ensuring trees are healthy, mature, and properly harvested

No roadside harvesting. No questionable sources. Just pure kratom from pristine environments.

Then the leaves come to our facility.

Inside Our Drying Facility: The Three Critical Differences

Multi-tiered drying racks allow optimal air circulation. Every leaf dries on clean, food-grade mesh netting

When you look at these images, you're seeing something most customers never get to see: the exact moment when quality is preserved or destroyed.

Here's what makes our facility different:

1. Lifted From the Ground

See those wooden racks? Everything is elevated on clean, tiered shelving systems.

Why this matters: Elevating the leaves prevents ground contamination – no dirt, no debris, no animals, no foot traffic. Air circulates freely underneath and above, creating even drying conditions.

Traditional ground drying means contamination is inevitable. Our system makes contamination impossible.

2. Clean Food-Grade Netting

Every leaf dries on clean, food-grade mesh netting – never plastic tarps, never concrete, never bamboo mats that have dried other crops.

Why this matters: The mesh allows air to circulate around every leaf. Moisture escapes evenly. There's no trapped humidity that could cause mold or degradation. And the food-grade material means zero chemical contamination.

We clean these nets between batches. This isn't just about kratom – this is about food safety standards.

3. Controlled Light Exposure

Notice the structure? Corrugated metal roof with ventilation, but no direct sunlight hits the leaves.

Why this matters: This is the most critical factor for preserving alkaloids. We control exactly how much light reaches the leaves. They dry in bright, airy conditions – but UV rays never directly strike them.

The result? Mitragynine levels stay stable. 7-hydroxymitragynine content is preserved. The kratom that reaches you has the full alkaloid profile that nature intended.

The Temperature and Humidity Factor

Inside this facility, we maintain consistent drying conditions:

- Stable temperature through natural ventilation (no over-heating)

- Controlled humidity that allows gradual moisture reduction

- Steady air flow that prevents mold while protecting alkaloids

Compare this to roadside drying: scorching heat during the day, moisture at night, inconsistent results, degraded quality.

Our facility gives every batch the exact conditions needed to preserve quality.

What This Means for You

When you order kratom from Kratom Powder Europe, you're not getting leaves that were dried on a plastic sheet next to a road.

You're getting kratom that was:

- ✅ Harvested from pristine jungle or controlled fields

- ✅ Transported immediately to our facility

- ✅ Dried in controlled, contaminant-free conditions

- ✅ Protected from UV degradation

- ✅ Handled with food-safety standards

- ✅ Tested for alkaloid content and purity

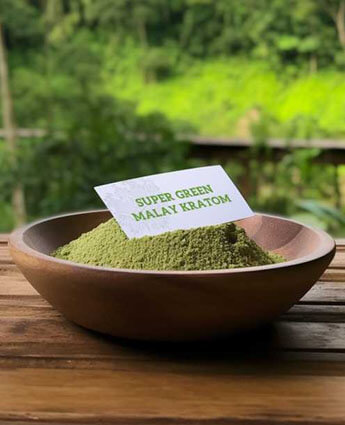

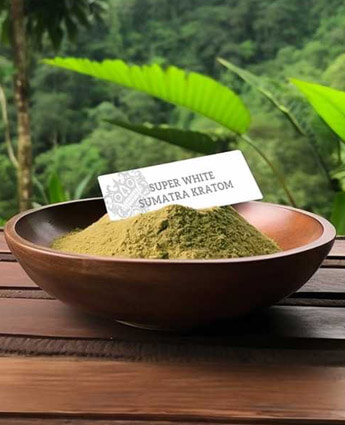

This is why our Maeng Da hits harder. Why our Red Borneo is so consistent. Why customers tell us our kratom is different from anything they've tried before.

It's not magic. It's just respecting the plant and the process.

The Difference

Ten years ago, we could have taken the easy route. Buy from middlemen, accept whatever quality they offered, compete on price.

Instead, we built infrastructure in one of the most remote regions of Borneo. We invested in relationships with local farmers. We created systems that prioritize quality over profit margins.

Because we believed you deserved better than gas station kratom. Better than products dried in questionable conditions. Better than alkaloid-degraded leaves sold as "premium."

These images show you the difference. This facility represents our commitment to giving you kratom the way it should be: pure, potent, and properly processed.

Experience the Difference

Ready to try kratom that's actually been treated with respect?

Every strain. Every batch. Dried in these facilities. Tested for quality. Shipped fresh to your door.

This is quality kratom. This is kratom done right.

Have questions about our drying process, our sourcing, or our quality standards? We're always happy to share more about what makes our kratom different. Email us at [email protected]

.jpg)