How is kratom powder produced?

How is Kratom Produced?

Discovering the Journey from Tree to Powder

Kratom, a natural botanical with the scientific name Mitragyna speciosa, has become a topic of interest around the world. Kratom’s line from the original tree to the finished product is an extensive process with deep roots in both ancient tradition and modern technology. This Kratom production process breakdown shines a light on the commitment to quality and sustainability that has given longevity to this ancient technique.

Kratom's Natural Habitat: The Foundation of Quality

The story of Kratom begins in the tropical rainforests of countries like Thailand, Malaysia, and Indonesia. Here the Kratom tree thrives in its natural habitat, growing into a tree well over 18 meters in height. The cultivation of Kratom itself is a testament to the natural order that exists between nature and the traditional agricultural practices of the region. Kratom is allowed to grow under conditions that meet the most rigorous standards found anywhere in the world related to the growth, maturity, and potency of the leaves. Our Kratom is harvested in putussibau kalimantan.

The Art of Harvesting: Picking and Collecting Leaves

Harvesting Kratom is a skill honed by generations, requiring patience and precision. The process involves careful selection, where leaves are picked based on their maturity and alkaloid content. This stage is crucial, as the color of the leaf's veins indicates the balance of alkaloids, which plays a significant role in the leaf's eventual effects.

The Critical Role of the Drying Process

The drying process is a pivotal step in Kratom production, significantly impacting the quality and efficacy of the final product. It's essential to understand that not every Kratom producer adheres to high standards of quality control or employs hygienic methods during the drying phase. Some may expose the leaves to uncontrolled environments, where they are susceptible to contaminants and inconsistent drying conditions.

An illustration of the drying process by some Kratom producers: We believe that Kratom should not be dried in direct sunlight, in open areas where people walk barefoot and animals roam freely.

Our Kratom Drying Facilities

At our facility, we prioritize the integrity of the drying process by utilizing a closed-off and clean drying room. This controlled environment ensures that each leaf is dried under optimal conditions, free from external contaminants and variations in temperature and humidity that can degrade Kratom's quality.

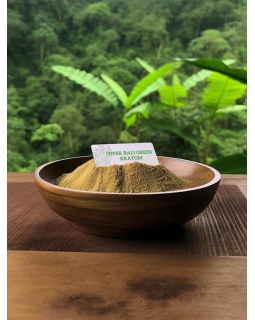

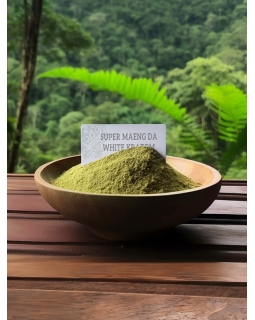

Transforming Leaves into Powder

Once harvested, the leaves undergo a meticulous process of drying and fermentation, which can vary depending on the desired outcome of the powder. This stage is where the leaves transform in texture and composition, preparing them for the final step of grinding into the fine powder that Kratom users are familiar with.

Sustaining Quality and Community: Beyond Production

The production of Kratom is not just about the final product but also about sustaining the communities and natural environments where Kratom is grown. Direct sourcing and ethical practices ensure that the benefits extend beyond the consumer, supporting the well-being of growers and preserving the ecological balance.

The Future of Kratom: Innovation and Advocacy

As Kratom continues to gain popularity, innovations in production and processing are emerging. Alongside, advocacy and education play vital roles in navigating the challenges of regulation and misinformation, paving the way for Kratom's future.

In conclusion, the production of Kratom is a complex interplay of tradition, skill, and care for quality and sustainability. From the lush forests of Southeast Asia to the hands of users around the world, Kratom's journey is a testament to the plant's enduring significance and the communities that nurture it.